Metal Bending Service

Explore MY Prototyping's outstanding metal bending services for achieving top-notch custom prototypes and production parts. Experience the best possible bending results at an affordable cost with fast turnarounds. Elevate your metal fabrication projects with our precision and efficiency.

Free quotation with DFM review within 1 day

Manufacture time as fast as 1 day

ISO 9001:2015 certificated

24Hrs

Instant Quotes

1 pc

MOQ

24/7

Engineer Service

99.5%

On time Performance

14 +

Years in Businsse

What Is Metal Bending

Unlock the secrets of effective metal bending, where controlled force transforms materials without compromise. Explore diverse metal bending techniques, enabling the creation of intricate shapes and geometries tailored to your specific needs. Immerse yourself in the art and science of metal bending, where precision meets the freedom of form, pushing the boundaries of what’s possible in fabrication

- Part Accuracy: With the right design and program input, the CNC machine controls the bending process to ensure that every bend is done at the exact angle and at the right length. This increases the accuracy and repeatability of the process.

- Smooth Finishes: An efficient bending process does not involve welding, ensuring no marks are left on the custom metal parts. CNC sheet metal bending services are also compatible with various finishing processes to provide better aesthetic results.

- Maximum Productivity: The sheet metal bending process can be easily synchronized with an automated set-up to allow the bending tool to complete the process within the shortest period. This capability ensures maximized output.

- Cost-effective: Production for Small Volume The automation of the bending process for maximum productivity ensures cost-effectiveness. Labor requirements are also low, ensuring that the operation is relatively inexpensive.

Why Choose Us for Metal Bending

At MY Prototyping, we employ the latest and most effective metal bending technology to achieve the best result. Metal bending requires the highest degree of precision to meet industry demands. MY Prototyping is a certified company with the right tools, expertise, and experience to offer precise prototypes and production parts.

Fast Quotation

Get fast, transparent pricing with our quotation , streamlining your decision-making process and accelerating project initiation for your sheet metal needs

Assured High Quality

We ensure your parts are flawless with ISO-certified quality, comprehensive reports, and rigorous inspections for dimensional accuracy and functionality, solving critical reliability concerns.

Fast Turnaround

We guarantee lead times as fast as 3 days, leveraging infinite capacity and flexible shipping options. Accelerate your sheet metal projects, ensuring timely delivery and a competitive edge.

Sheet Metal Engineering Support

Overcome complex design challenges with MY Prototyping's engineering experts. Our expertise ensures precise, innovative solutions, reducing your workload and elevating product quality.

MY Prototyping Metal Bending Services

Upload drawings on our website.

You will get a fast quotation within 24 Hrs.

You could talk to our expert for drawings analysis.

Start a project today!

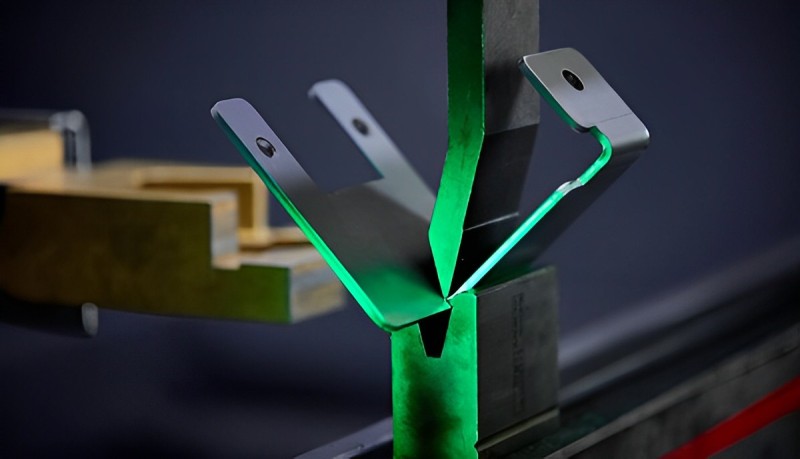

Metal Bending: From Prototyping to Production

Discover the versatility of MY Prototyping’s custom metal bending services, seamlessly adapting to applications ranging from mold tooling to rapid prototyping and beyond. Unlock precision and flexibility in your metal fabrication journey with our advanced bending capabilities, ensuring excellence from initial prototypes to full-scale production

-1024x576.jpg)

Custom metal fabrication can be formed into 2D shaped profiles from various metals, creating functional molds for specific parts.

Provide flexibility and precision to ensure that the preliminary version of the metal part or sheet is accurate and functional before moving into full-scale production.

From rich selections of materials to bent parts manufacturing and assemblies, to flexible delivery, we provide end-to-end high-volume production solutions.

How MY Prototyping Custom Sheet Metal Fabrication Works?

Experience seamless custom sheet metal fabrication with MY Prototyping. Connect with our domestic sheet metal supplier, and watch your designs come to life. From initial prototypes to finished assemblies, our skilled fabricators use precise machine code to transform your CAD designs. Every step, from stretching and cutting to welding and fastening, adheres to strict quality standards, ensuring the end-use product meets your unique specifications.

Instant Quote

To start, simply select a manufacturing process and upload a 3D CAD file.

Order Evaluation and Processing

CAD confirmation and optimization

No Minimum Order Quantity

Flexible order quantities from 1 to 10,000

Production

Fast, precise, and professional manufacturing for your product

Quality Control and Delivery

100% outgoing QC check. Parts shipped using DHL Express or similar.

Sheet Metal Fabrication Materials

Choose from a diverse range of sheet metal materials, including aluminum, brass, stainless steel, and copper. Elevate the durability and aesthetics of your metal components with our versatile material selection..

Aluminum

Aluminum with its lightweight yet robust nature, offers enhanced durability without excess weight. Its superior malleability allows precise shaping, ideal for intricate designs.

AL5052

AL5754

AL6061

AL6082

Copper

Copper’s advantages are clear: unparalleled electrical conductivity, thermal efficiency, and natural resistance to corrosion, ensuring longevity and performance in fabrications.

CU1020

CU1100

CU2100

CU2200

CU2300

CU2400

CU2600

Stainless Steel

Renowned for its durability and resistance to staining, stainless steel ensures longevity and maintains its appearance, even in harsh environments.

301 303 304

316

420 430

Titanium

Titanium has a number of material properties that make it the ideal metal for demanding applications. These properties include excellent resistance to corrosion, chemicals and extreme temperatures. The metal also has an excellent strength-to-weight ratio.

Price: $$$

Lead Time: < 10 days

Wall Thickness: 0.75 mm

Tolerances: ±0.125mm (±0.005″)

Max part size: 200 x 80 x 100 cm

Surface Finishing Options for Metal Bending

Choose from an extensive list of finishing options to enhance the surfaces of your custom laser-cut parts and products. These options improve cosmetic appearance, corrosion resistance, and overall durability.

| Name | Description | Materials | Color | Texture | |

|---|---|---|---|---|---|

| Anodizing | Anodizing improves corrosion resistance, enhancing wear resistance and hardness, and protecting the metal surface. Widely used in mechanical parts, aircraft, and automobile parts, precision instruments, etc. | Aluminum | Clear, black, grey, red, blue, gold. | Smooth, matte finish. |

| Bead Blasting | Bead blasting results in parts with a smooth surface with a matte texture. Used mainly for visual applications and can be followed by other surface treatments. | ABS, Aluminum, Brass, Stainless Steel, Steel | N/A | Matte |

| PowderCoating | Powder coating is a type of coating that is applied as a free-flowing, dry powder. Unlike conventional liquid paint which is delivered via an evaporating solvent, powder coating is typically applied electrostatically and then cured under heat or with ultraviolet light. | Aluminum, Stainless Steel, Steel | Black, any RAL code or Pantone number | Gloss or semi-gloss |

| Electroplating | Electroplating can be functional, decorative or corrosion-related. Many industries use the process, including the automotive sector, in which chrome-plating of steel automobile parts is common. | Aluminum, steel, stainless steel | N/A | Smooth, glossy finish |

| Polishing | Polishing is the process of creating a smooth and shiny surface, either through physical rubbing of the part or by chemical interference. The process produces a surface with significant specular reflection, but in some materials can reduce diffuse reflection. | Aluminum, Brass, Stainless Steel, Steel | N/A | Glossy |

| Brushing | Brushing is a surface treatment process in which abrasive belts are used to draw traces on the surface of a material, usually for aesthetic purposes. | ABS, Aluminum, Brass, Stainless Steel, Steel | N/A | satin |

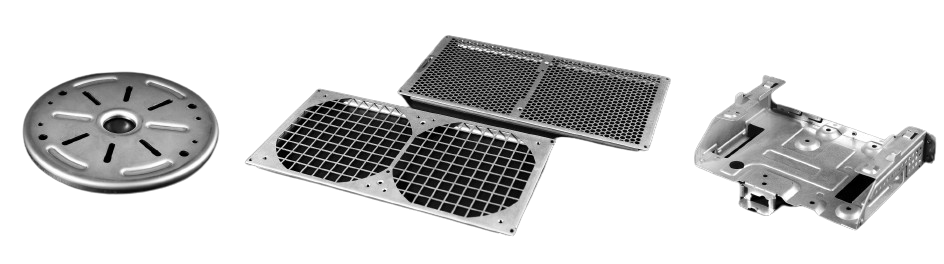

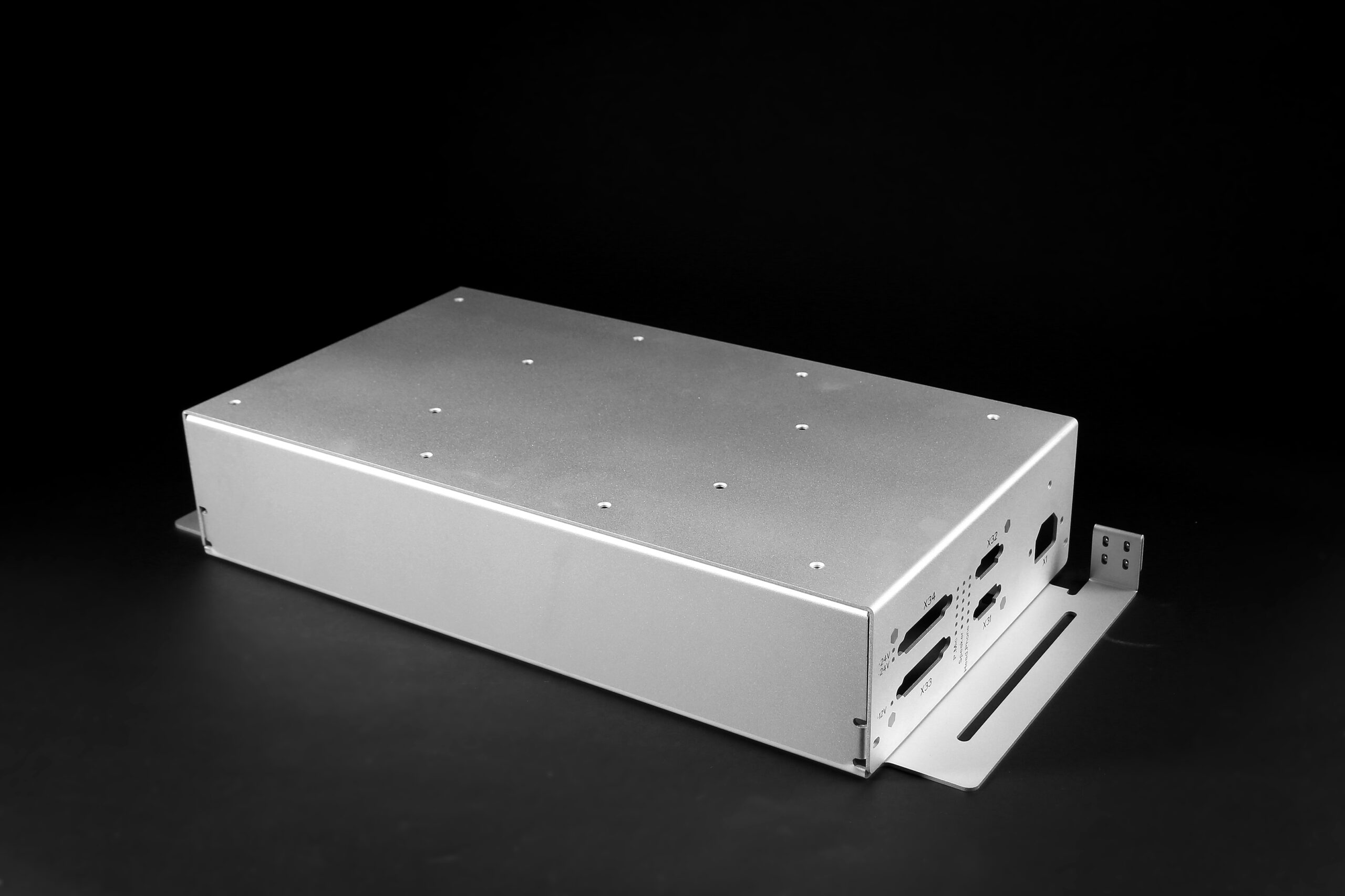

Metal Bending Case Study

For numerous years,Experience precision and innovation as we tackle challenges, turning them into opportunities. From intricate designs to flawless execution, explore our commitment to quality in the metal bending industry.

Metal Bending for Various Applications

Many industries worldwide are increasingly adopting laser cutting technology due to its numerous advantages, including precision, tight tolerance, flexibility, clean finish, enhanced productivity, and design complexity. Whether for prototyping or full-scale manufacturing, transitioning to laser cutting proves to be a time and cost-saving solution.