Rapid prototypes, low-volume, high-volume production

Communications Industry

Explore our streamlined manufacturing processes, offering rapid prototyping and custom production for communication devices at competitive prices. Experience efficiency and precision in every stage of your product development.

High-quality communication parts

Instant pricing & free DFM feedback

24/7 engineering support

Why Choose MY Prototyping

Choose MY Prototyping for your communication components manufacturing needs and experience efficiency and cost-effectiveness at its best. With the latest technologies and advanced manufacturing processes, coupled with our extensive technical knowledge and experience, we stand as a leading force in the production of electronic devices.

Strong Manufacturing Capabilities

As an ISO 9001 certified manufacturing company, MYprototyping's production line is equipped with advanced technologies to ensure manufacturing accuracy and precision. Every aerospace part meets the correct dimensional specifications, structural strength, and performance.

Get Instant Quotation

Enhance your manufacturing experience through our intelligent instant quotation platform. Upload your CAD files, receive instant quotes for your aerospace parts, and initiate the ordering process. Take control of your orders with efficient order tracking and management.

Tight Tolerance Aerospace Parts

We can machine aerospace parts with tight tolerances up to +/-0.001 inches. We adhere to the ISO 2768-m standard tolerance for metals and ISO-2768-c for plastics. Our manufacturing capabilities can also accommodate intricate designs for custom part manufacturing.

Fast Cycle Time

With quotes within minutes and parts within days, you can reduce cycle times by up to 50% with MYprototyping. A perfect combination of advanced technologies and extensive technical experience enables us to deliver superior-quality aerospace parts with faster lead times.

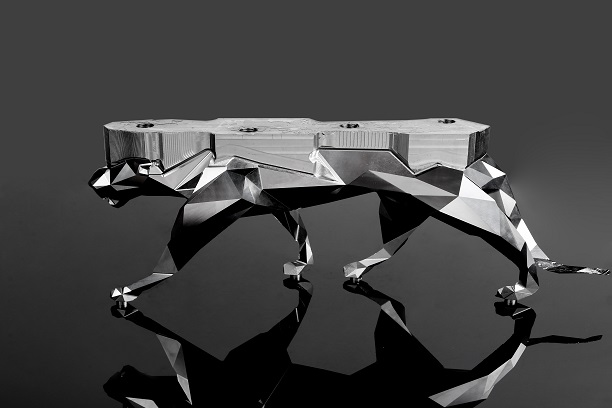

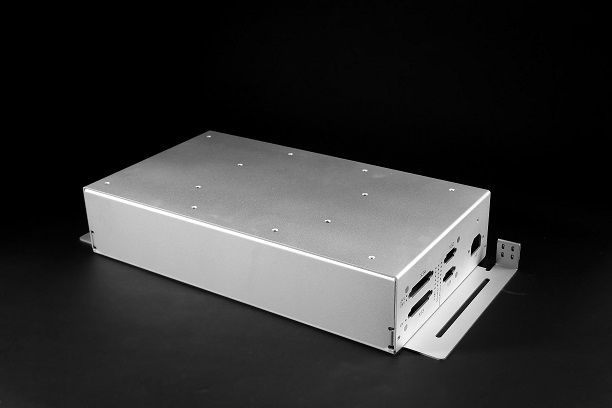

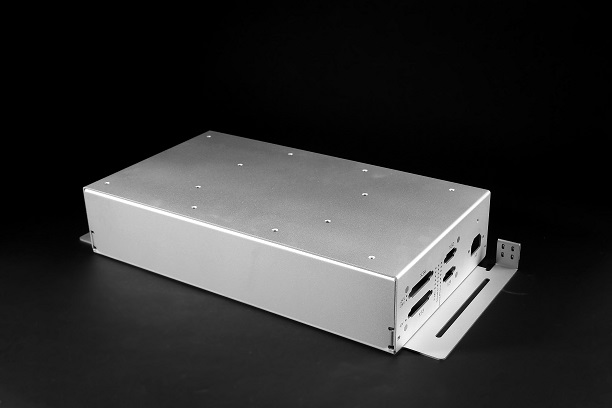

Sheet metal Communications Prototypes

At MY Prototyping, a skilled team used sheet metal fabrication to create an innovative communications prototype. Precision in material selection and design resulted in a durable and efficient device, showcasing MY Prototyping’s commitment to advancing communication technology. The outcome is a sleek and cutting-edge prototype.

Trusted by Fortune 500 Communications Companies

Telecommunication equipment manufacturers

Power grids providers

Device networking and industrial communication suppliers

Hazard detection specialists

Access control system providers

Security system suppliers

Wireless alarm systems suppliers

Navigational instruments manufacturers

Electric Bikes and Scooters

Communications Prototyping & Part Manufacturing Services

Step into the world of seamless connectivity with our expertise in the communications industry. As technology evolves, we collaborate with leading innovators to create prototypes and products that connect and transform the way we live. Our customer-centric services empower you to iterate swiftly, providing customized solutions to meet the dynamic demands of the ever-evolving market.

Sheet metal fabrication

Sheet metal fabrication

CNC Machining

CNC Machining

injection molding

injection molding

3D printing

3D Printing

Applications of Communication Components

Discover the myriad applications of our electronic communication components at MY Prototyping. Our precision-crafted parts, ranging from fixtures to circuit boards, electronic enclosures, and chassis, uphold the highest standards of performance and durability. Explore how our components contribute to the seamless functioning of communication systems across diverse applications.

Electronic cabinets and enclosures

Heat sinks

GPS devices

Rackmount assemblies

Magnetic receivers

Connectors

Light detection systems

Phone switchboards

Transformers and audio equipment

Switches

TESTIMONIALS

A customer’s words have a more substantial impact than a company’s claims – and see what our satisfied customers have said regarding how we fulfilled their requirements

Custom Parts for Communications Industry

Elevate your projects in the Communications Industry with our tailor-made components. From intricate designs to flawless execution, experience the precision and reliability that set us apart. Boost your connectivity solutions with MY Prototyping’s commitment to excellence.

Explore More Industries We Support

Years of serving various clients gave us the experience and knowledge needed to support numerous industries. Click on the link below to know more.

Start a new project production today!

Explore Related Resources

How Precision Sheet Metal Fabrication Improves Modern Cars’ Performance

Precision sheet metal fabrication is one of the most important processes in automotive engineering, which makes it possible to fabricate …

How Rapid Injection Molding Lowers Production Costs in the Drone Industry?

Are high production costs and slow timelines keeping your drone business stuck on the ground? If so, Rapid Injection Molding …

ISO 2768-mk – The basics of the general tolerance standard

Every feature on a product or part has a size and a geometric shape. To ensure that the size and …