Custom CNC Machining Services

Explore our comprehensive online CNC machining services, ranging from prototypes to on-demand production parts. Receive an instant quote for your metal or plastic projects, choosing from a diverse selection of 40+ materials and 10+ surface finishes. Rest assured with our ISO 9001:2015 certification.

Instant CNC quotes

Tolerances down to 0.01mm (±0.0004″ )

Machined parts as fast as 3working days

24Hrs

Instant Quotes

1 PC

MOQ

7/24

Engineer Service

99.5%

On time Delivery

14+

Years in Business

MY Prototyping CNC Machining Services

MY Prototyping offers custom CNC machining services tailored to the needs of engineers, product developers, and designers. Whether it’s prototyping or low-volume production, our ISO 9001 certified CNC machine shops excel in producing parts with precision, even for intricate designs with tight tolerances. Experience the efficiency of our fast CNC machining capabilities, ensuring the delivery of quality custom machined parts within just one day.

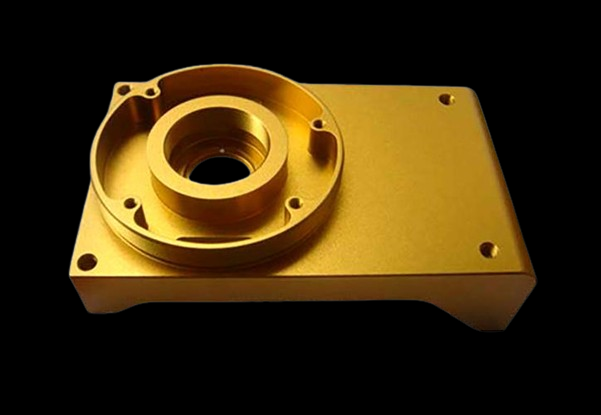

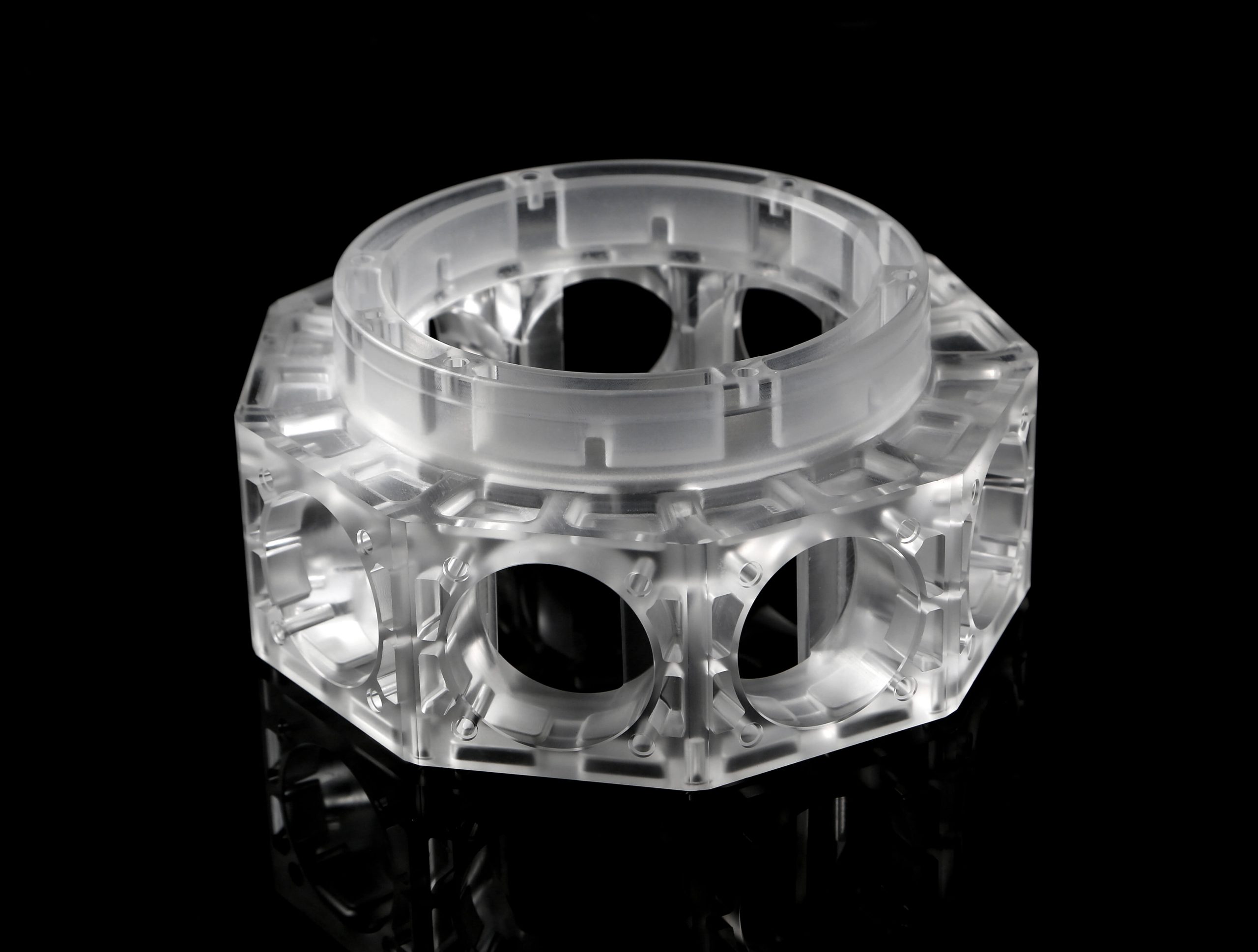

Custom CNC Milling Services

Experience the precision of CNC milling with MYprototyping's multi-axis capabilities, including 3, 4, and 5-axis machining processes. Our CNC milling services empower the creation of detailed and specific geometries from metal or plastic blocks, ensuring exceptional accuracy and quality.

Custom CNC Turning Services

Utilize our CNC turning services that leverage CNC lathes and turning centers to shape metal rod stock, with a primary focus on cylindrical parts. Ensure your components achieve consistent dimensions and smooth finishes.

-1024x576.jpg)

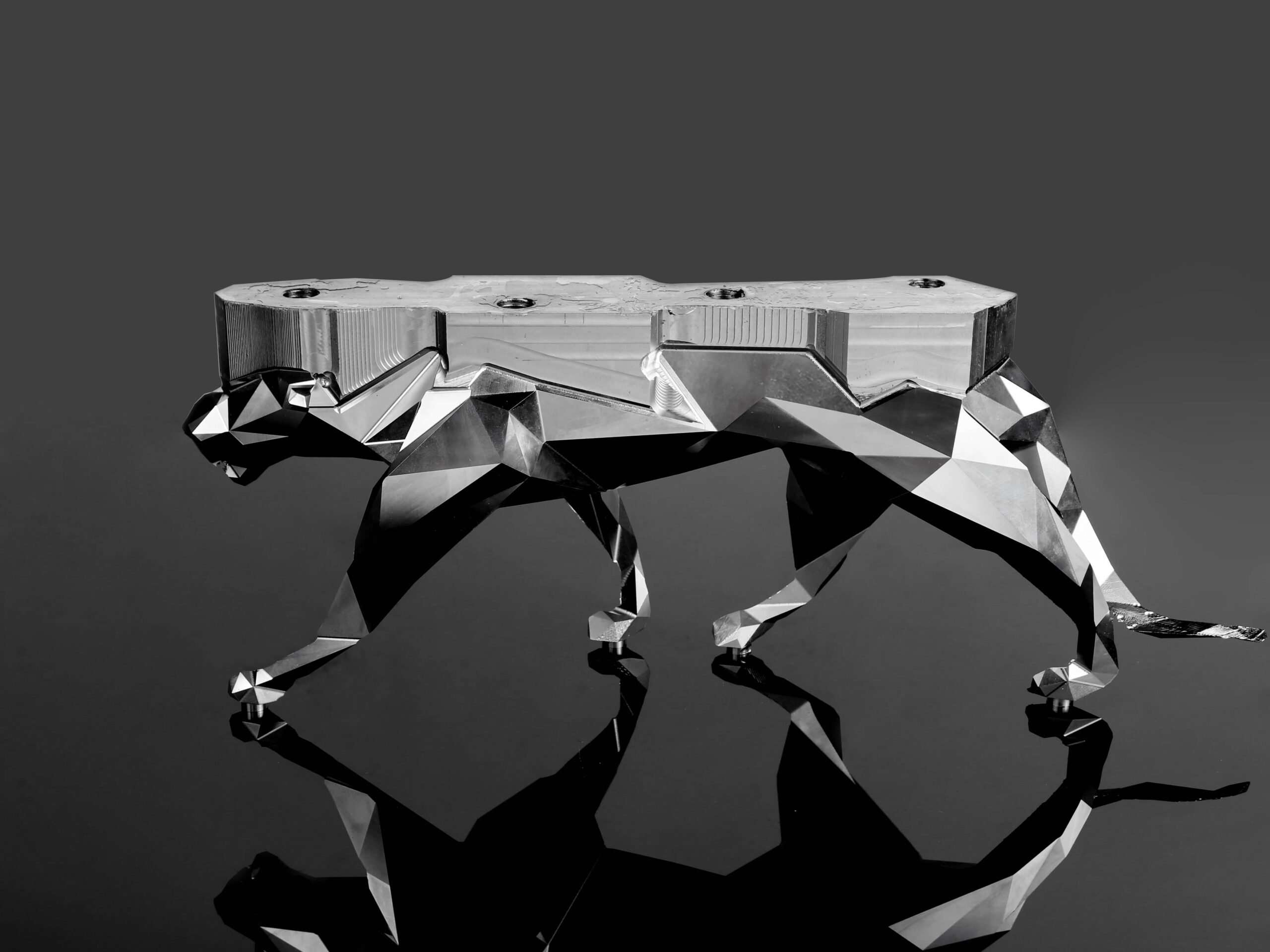

5 Axis CNC Machining

Experience precision with MY Prototyping's 5-axis machining. We craft complex parts swiftly and accurately using advanced CNC machines. Elevate your prototyping with our expertise and cutting-edge technology.

Online quote for CNC Machining

Upload drawings on our website.

You will get a fast quotation within 24-48 Hrs.

You could talk to our expert for drawings analysis.

Start a project today!

Order Process

MY prototyping delivers high-quality precision machining with an incredible range of manufacturing capabilities. From prototyping to mass production, we help manufacture products with complex geometries and high aesthetic demands. Our skilled experts and advanced technologies allow us to deliver an extensive range of on-demand manufacturing services.

Instant Quote

To start, simply select a manufacturing process and upload a 3D CAD file.

Order Evaluation and Processing

CAD confirmation and optimization

No Minimum Order Quantity

Flexible order quantities from 1 to 10,000

Production

Fast, precise, and professional manufacturing for your product

Quality Control and Delivery

100% outgoing QC check. Parts shipped using DHL Express or similar.

CNC machining material

MY prototyping delivers high-quality precision machining with an incredible range of manufacturing capabilities. From prototyping to mass production, we help manufacture products with complex geometries and high aesthetic demands. Our skilled experts and advanced technologies allow us to deliver an extensive range of on-demand manufacturing services.

Aluminum

Aluminum is a highly ductile metal, making it easy to machine. The material has a good strength-to-weight ratio and is available in many types for a range of applications.

Price: $

Lead Time: < 10 days

Tolerances: ±0.125mm (±0.005″)

Max part size: 200 x 80 x 100 cm

Copper

Copper displays excellent thermal conductivity, electrical conductivity and plasticity. It is also highly ductile, corrosion resistant and can be easily welded.

Price: $$$

Lead Time: < 10 days

Wall Thickness: 0.75 mm

Tolerances: ±0.125mm (±0.005″)

Max part size: 200 x 80 x 100 cm

Stainless Steel

Stainless steel is the low carbon steel that offers many properties that are sought after for industrial applications. Stainless steel typically contains a minimum of 10% chromium by weight.

Price: $$

Lead Time: < 10 days

Wall Thickness: 0.75 mm

Tolerances: ±0.125mm (±0.005″)

Max part size: 200 x 80 x 100 cm

Plastic

Plastics are a popular choice for CNC machining due to their versatility, cost-effectiveness, and faster machining times. Explore our CNC machining services with a variety of common plastics available.

| POM | PEEK | HDPE | PET |

| Nylon | PTFE | PVC | PP |

| ABS | PC | PMMA |

CNC Machining Surface Finishes

CNC machining leaves visible tool marks while creating shapes by removing portions of the block’s surface. If you prefer a polished look, choose from our selection of surface finishes at MY Prototyping. These finishes not only enhance functionality but also contribute to the aesthetics of your custom parts.

| Name | Description | Materials | Color | Texture | |

|---|---|---|---|---|---|

| Anodizing | Anodizing improves corrosion resistance, enhancing wear resistance and hardness, and protecting the metal surface. Widely used in mechanical parts, aircraft, and automobile parts, precision instruments, etc. | Aluminum | Clear, black, grey, red, blue, gold. | Smooth, matte finish. |

| Bead Blasting | Bead blasting results in parts with a smooth surface with a matte texture. Used mainly for visual applications and can be followed by other surface treatments. | ABS, Aluminum, Brass, Stainless Steel, Steel | N/A | Matte |

| PowderCoating | Powder coating is a type of coating that is applied as a free-flowing, dry powder. Unlike conventional liquid paint which is delivered via an evaporating solvent, powder coating is typically applied electrostatically and then cured under heat or with ultraviolet light. | Aluminum, Stainless Steel, Steel | Black, any RAL code or Pantone number | Gloss or semi-gloss |

| Electroplating | Electroplating can be functional, decorative or corrosion-related. Many industries use the process, including the automotive sector, in which chrome-plating of steel automobile parts is common. | Aluminum, steel, stainless steel | N/A | Smooth, glossy finish |

| Polishing | Polishing is the process of creating a smooth and shiny surface, either through physical rubbing of the part or by chemical interference. The process produces a surface with significant specular reflection, but in some materials can reduce diffuse reflection. | Aluminum, Brass, Stainless Steel, Steel | N/A | Glossy |

| Brushing | Brushing is a surface treatment process in which abrasive belts are used to draw traces on the surface of a material, usually for aesthetic purposes. | ABS, Aluminum, Brass, Stainless Steel, Steel | N/A | satin |

CNC Machining Case Study

Meet Marco, a proficient mechanical engineer from Italy who utilized MY Prototyping’s state-of-the-art 5-axis CNC machining services to bring his vision to life. The result? A high-quality passive exoskeleton prototype designed to enhance human power and reduce physical fatigue.

Why Choose Our Custom CNC Machining Service

MY prototyping delivers high-quality precision machining with an incredible range of manufacturing capabilities. From prototyping to mass production, we help manufacture products with complex geometries and high aesthetic demands. Our skilled experts and advanced technologies allow us to deliver an extensive range of on-demand manufacturing services.

Instant Quote

get instant CNC quotes by simply uploading your design files. Our digital quoting analyzes service your part geometry, and provides real-time & competitive pricing feedback.

Consistent High Quality

Rely on our advanced CNC capabilities, stringent quality checks, and continuous communication to guarantee that each machined piece you receive consistently meets the highest standards, ensuring reliability in every project.

Fast and Reliable Delivery

Benefit from our robust manufacturing capacity at MY Prototyping, ensuring swift turnaround for CNC machined parts. Our diverse shipping options further guarantee on-time delivery, eliminating typical hassles in the process.

Professional Engineering Support

Wherever you are, access our 24/7 engineering support year-round. Our seasoned engineers are ready to offer the most suitable solutions for your part design, material selection, surface finishing, and lead time considerations.

Our CNC Machining for Various Industrial Applications

MY Prototyping’s custom CNC machining services cater to a wide range of industrial applications, meeting diverse and specific requirements across industries.

Robotics

Medical devices

Automotive

Aerospace

Home Appliace

New energy

CNC Machining Overview

1、What's CNC Machining?

CNC Machining, or Computer Numerical Control Machining, is a manufacturing technique utilizing computer-controlled devices to remove layers from a material, creating detailed parts or components. Through a combination of tooling and precise machine movement, it produces parts to exact specifications.

2、What's the CNC Machining Process?

The CNC machining process begins with designing a part in CAD software. This design is then converted into a set of machine commands using CAM software. The CNC machine reads these commands to precisely cut and shape the material, resulting in a finished part that mirrors the digital design.

3、What are the Advantages of CNC Machining?

CNC Machining offers unparalleled precision and repeatability, making it a top choice for industries requiring intricate parts. Its ability to handle a variety of materials, from metals to plastics, combined with fast production times and consistent quality, makes it an essential method in modern manufacturing.

4、What's the Difference Between 3D Printing and CNC Machining?

3D printing is an additive manufacturing method, building parts by depositing material layer by layer. In contrast, CNC machining is a subtractive method, starting with a solid block of material and removing sections until the desired part is achieved. While 3D printing is often favored for complex geometries and rapid prototyping, CNC machining excels in durability, precision, and material versatility.