Custom 3D Printing Serive

Upload drawings on our website. You will get a fast quotation within 24-48 Hrs. You could talk to our expert for drawings analysis. Start a project today!

Tolerance down to ±0.2mm

Plastic and metal 3D printing

Technical support and design guide

24Hrs

Instant Quotes

1 pc

MOQ

24/7

Engineer Service

99.5%

On time Delivery

14+

Years in Business

Custom 3D Printing Services

Discover excellence with MY Prototyping’s 3D printing services. Perfect for rapid prototypes and intricate functional parts, our cutting-edge facilities are operated by seasoned experts. Utilizing leading additive manufacturing technologies, including Selective Laser Sintering, Stereolithography, HP Multi Jet Fusion, and Selective Laser Melting, we ensure the swift delivery of finely-crafted, precise 3D printed prototypes and end-use parts. Ideal for projects of any scale,MYprototyping guarantees quality from small batches to extensive production needs.

SLA 3D Printing

As a cornerstone in additive manufacturing, SLA 3D printing stands out for its unparalleled precision and superior surface quality. This transformative technology delivers intricately detailed models and visual prototypes, guaranteeing high resolution and smooth surfaces, making it the ideal choice for complex geometries.

HP MJF 3D Printing

A groundbreaking technology, HP MJF 3D printing sets the standard for high-speed production and unwavering quality. Tailored for functional parts, this innovative method guarantees robust, intricate, and dimensionally precise prints endowed with exceptional mechanical properties."

SLS 3D Printing

Renowned for its strength and durability, SLS 3D printing emerges as a versatile method, perfect for crafting functional parts. This advanced technology produces complex, high-quality prints sans the necessity for support structures, granting unparalleled design freedom in the creative process

SLM 3D Printing

Revolutionizing manufacturing, SLM 3D printing melds metal powders into robust, intricate parts. Tailored for the aerospace and automotive industries, this cutting-edge technology ensures the creation of high-performance and durable components with complex geometries, setting new standards for precision and design excellence.

What is MY Prototyping 3D Printing Capability?

Explore the comprehensive overview of each 3D printing capability at MY prototyping, we manufacture the prototypes to mass production, revealing unique standards that empower informed decisions for your printing needs. Experience a new dimension of printing excellence with us, SLA,SLS,MJF,SLM

| Technology | Min. Wall Thickness | Layer Height | Max. Build Size | Dimension Tolerance | Standard Lead Time |

|---|---|---|---|---|---|

| SLA | 0.6 mm for unsupported walls, 0.4 mm for supported wall on both sides | 25 µm to 100 µm | 1400x700x500 mm | ±0.2mm (For >100mm, apply 0.15%) | 4 business days |

| SLS | 0.6 mm for unsupported walls, 0.4 mm for supported wall on both sides | 25 µm to 100 µm | 1400x700x500 mm | ±0.2mm (For >100mm, apply 0.15%) | 4 business days |

| MJF | At least 1mm thick; avoid overly thick walls | 25 µm to 100 µm | 1400x700x500 mm | ±0.2mm (For >100mm, apply 0.15%) | 4 business days |

| SLM | 0.8 mm | 30 – 50 μm | 5x5x5mm | ±0.2mm (For >100mm, apply 0.25%) | 6 business days |

Empowering Industries: 3D Printing Revolution Across Sectors

From aerospace to healthcare, our advanced 3D printing services transcend industries, transforming concepts into high-performing prototypes and serialized production parts. By optimizing manufacturing processes, we unlock new potentials and redefine the standards of innovation.”

Medical

MY prototyping delivers high-quality precision machining with an incredible range of manufacturing capabilities. From prototyping to mass production, we help manufacture products with complex geometries and high aesthetic demands. Our skilled experts and advanced technologies allow us to deliver an extensive range of on-demand manufacturing services.

Explore Custom 3D Printing Solutions

Seamlessly order precision prototypes, meticulous mass production, and expert manufacturing. Our rigorous approach guarantees your orders are handled with utmost care and efficiency.

Design Submission

Kick off the process by uploading your 3D model files online, or you could email us directly. Seamlessly supports various file formats such as [.STP], [.STEP], or [.STL], ensuring compatibility and ease of use.

Instant Quote & DFM analysis

Upon submitting your project, an immediate quote will be provided. Our sophisticated algorithms conduct a thorough analysis of your design, pinpointing potential manufacturability issues and fine-tuning for optimal printing efficiency.

High Precision Printing

Witness your design come to life with high-resolution 3D printers. Adhering to industry-leading standards, we guarantee unmatched precision and detail in every aspect, ensuring unparalleled accuracy.

Quality Guarantee

Subjected to thorough scrutiny, each part undergoes a meticulous inspection process. Our quality control regimen encompasses dimensional accuracy checks and surface finish examinations, ensuring that your parts not only meet but exceed exact specifications.

Packaging and Delivery Asurance

Upon approval,your 3D printing parts are careful packaging and swift shipping. We offer expedited and reliable delivery choices, ensuring your products reach you within as little as one day.

3D Printing Materials at MY Prototyping

At MY Prototyping,We offer a range of material choices for 3D printings materials. Encompassing plastics and metals , just like ABS, PC, PA (Nylon), Aluminum, and stainless Steel and Titanium material. For those with distinctive material needs, a selection of ‘Other’ is available on our quote configuration page. Our commitment is unwavering in ensuring the precise sourcing of materials according to your requirements.

ABS and Resins

Renowned for its strength, durability, and elevated temperature resistance, ABS stands out as a premier selection for 3D printing. Suited for functional prototypes and intricate designs, ABS guarantees dependable performance and a remarkable finish.

Technology: SLA

Color: White, Beige, Black, Red, Semi-transparent

Types:

– ABS Photosensitive Resin

– High Temperature Resistant 70°C Photosensitive Resin

– Black Toughness 70°C Heat-Resistant Photosensitive Resin

– Semi-Transparent – Photosensitive Resin

White Tough Resin

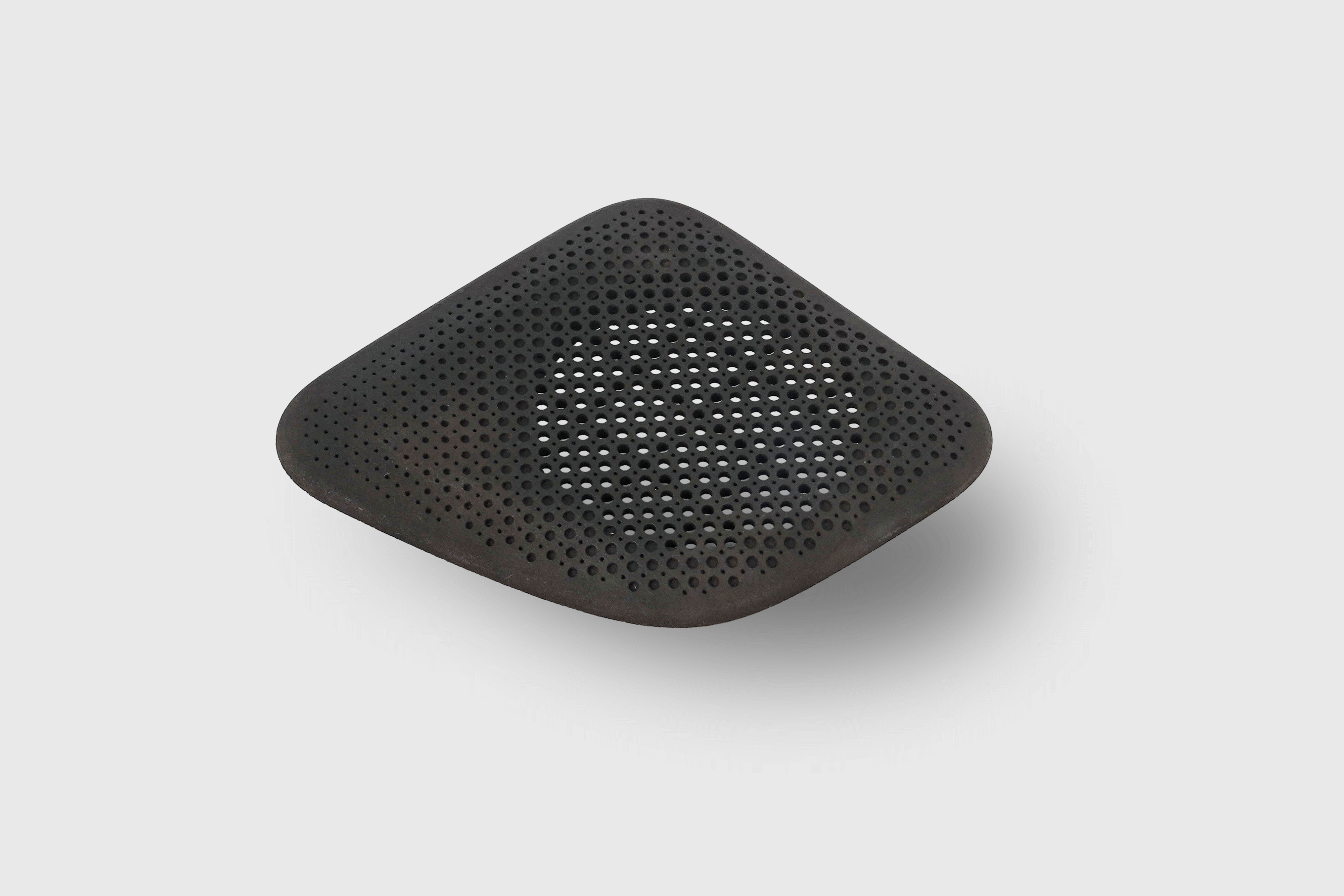

PA (Nylon)

Possessing outstanding strength, flexibility, and resistance to abrasion, Nylon emerges as an optimal choice for small quantities of prototypes and resilient end-use products. Its enduring durability and adaptability guarantee a high standard of quality in long-lasting prints.

Technology: MJF, SLS

Color: Original color, gray-black,

black painted

Types: HP Nylon

Aluminum

Aluminum metal 3D printing presents a distinctive combination of lightness and strength, coupled with exceptional thermal conductivity and resistance to corrosion. This renders it a premier choice for creating high-precision, durable prints.

Technology: SLM

Color: Silvery Gray

Type: ALSI10MG Aluminum Alloy

Stainless Steel

With unparalleled strength, resistance to corrosion and heat, and durability, stainless steel proves to be an ideal choice for industrial 3D applications. It guarantees the production of high-quality, precise parts endowed with excellent mechanical properties.

Technology: SLM

Color: Gray-black

Type: 316L

Titanium

With exceptional strength, resistance to corrosion and heat, and impressive durability, titanium stands out as an excellent option for a wide range of industrial applications. It guarantees the creation of precise, high-quality components with outstanding mechanical properties.

Technology: DMLS

Color: Gray-black

Type: Ti15-45

3D Printing surface finishing

Explore the detailed surface roughness metrics for various 3D printing techniques offered by My prototyping’s custom services in the table below. This comprehensive guide will assist you in selecting the most suitable printing technique for achieving the desired part texture and precision

| Printing Type Materia | Post-Printing Roughness | Post-Processing Technology | Roughness After Processing |

|---|---|---|---|

| SLA Photopolymer Resin | Ra6.3 | Polishing, plating | Ra3.2 |

| MJF Nylon | Ra6.3 | Polishing, plating | Ra3.2 |

| SLS White Nylon, Black Nylon, Glass-filled Nylon | Ra6.3-Ra12.5 | Polishing, plating | Ra6.3 |

| SLM Aluminum Alloy | Ra6.3-Ra12.5 | Polishing, plating | Ra6.3 |

| SL Stainless Steel | Ra6.3-Ra12.5 | Polishing, plating | Ra6.3 |

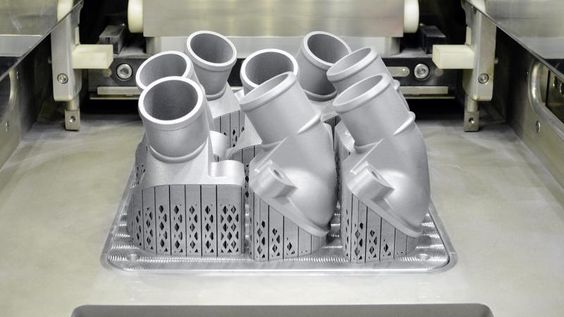

3D Printing Case study

The integral role of 3D printed prototypes in driving innovation and development within the automotive sector cannot be overstated. MY prototyping’s dependable 3D printing service proved instrumental in assisting our customers to efficiently fabricate lightweight, heat-resistant engine components for both prototyping and low-volume production. Witness the speed at which automotive engine parts can be produced through our advanced 3D printing facilities, ensuring the delivery of printed parts within a mere three days, all backed by our dedicated customer support.

Why Choose MY Prototyping for 3D Printing

Elevate your 3D printing experience with MY Prototyping. Our commitment to precision, promptness, and quality sets us apart. Choose us for innovative solutions, timely deliveries, and exceptional results. MY Prototyping – where your ideas take shape seamlessly.

Instant quote within 24Hrs

Experience the convenience of receiving an instant quote within 24Hrs. Our efficient and streamlined process ensures a swift response, allowing you to quickly proceed with your project without delays. At MY prototyping, we prioritize efficiency and responsiveness to meet your needs promptly.

High-Quality 3D Printing

Our dedication to excellence involves the utilization of cutting-edge technology, rigorous quality control processes, and advanced materials. This commitment ensures the durability and precision of our high-quality products, minimizing the need for rework and ultimately contributing to the success of your project.

Quick response

Experience swift outcomes with our streamlined processes and state-of-the-art equipment, addressing your urgent needs by delivering high-quality printed items quickly. This efficiency significantly reduces wait times, enhancing your project's pace and overall productivity.

Expert Supporting

Benefit from a team of experienced 3D engineers offering personalized guidance for every project. Resolve complex design challenges, enhance print success, and elevate customer satisfaction—all tailored to meet your unique specifications.

3D printings application in different industries

In healthcare, it creates personalized implants. Automotive benefits from rapid prototyping, reducing development time. Aerospace utilizes lightweight, intricate components. Manufacturing sees cost-effective production and rapid prototyping. Architecture benefits from detailed scale models. In fashion, it enables customized designs. This versatile technology continues to shape and redefine diverse sectors, showcasing its adaptability and transformative impact.

Automotive

Aerospace

Home Appliance

Robotics

Communication

3D Printing Outline

MY Prototyping delivers high-quality precision machining with an incredible range of manufacturing capabilities. From prototyping to mass production, we help manufacture products with complex geometries and high aesthetic demands. Our skilled experts and advanced technologies allow us to deliver an extensive range of on-demand manufacturing services.

1.What's 3D Printing?

3D printing, also known as additive manufacturing, is a transformative technology that involves creating three-dimensional objects layer by layer from digital models. This process allows for the fabrication of complex and customized shapes, making it valuable across various industries for prototyping, production, and innovation.

2.What Are the Primary Applications of 3D Printing?

3D printing finds diverse applications across industries. In healthcare, it aids in creating personalized implants and prosthetics. Automotive and aerospace benefit from rapid prototyping and lightweight component production. Manufacturing utilizes it for cost-effective production. Architecture sees applications in detailed scale models. Additionally, 3D printing is employed in fashion for customized designs. Its versatility spans multiple sectors, showcasing its adaptability and impact.

3.What Resolution or Precision Can 3D Printers Achieve?

The resolution or precision of 3D printers varies depending on the technology and equipment used. In general, desktop FDM (Fused Deposition Modeling) printers typically achieve layer resolutions in the range of 0.1 to 0.3 millimeters. SLA (Stereolithography) and SLS (Selective Laser Sintering) printers, which are more advanced, can achieve finer resolutions ranging from 0.025 to 0.1 millimeters. Professional and industrial-grade 3D printers can achieve even higher precision, sometimes reaching resolutions below 0.025 millimeters. It’s essential to choose a 3D printer with the appropriate resolution for your specific project requirements.

4.What's the Difference Between 3D Printing and CNC Machining?

3D printing and CNC machining are distinct manufacturing processes. 3D printing, or additive manufacturing, builds objects layer by layer from digital models. It is advantageous for complex geometries and rapid prototyping.CNC machining, or subtractive manufacturing, involves cutting away material from a solid block to create a part. It is suitable for high-precision, detailed components.

While 3D printing offers design flexibility, CNC machining provides superior accuracy and material options. The choice between them depends on project requirements, materials, and desired outcomes.

3D Prints FAQs

At MY Prototyping, questions mostly asked by our clients. Find concise answers to key questions, from technology basics to material options and project considerations. Enhance your understanding of 3D printing with our informative FAQ.

The precision of 3D printing can be exceptionally high, with our standard tolerance set at ± 0.1mm. However, the actual tolerance may vary based on the complexity of your part. Feel free to upload your 2D design files, and we will assess and determine the specific tolerances tailored to your project requirements.

Several crucial factors influence the printing time, including part size, height, complexity, and the chosen printing technology. At MY prototyping, we pride ourselves on swift project completion, with the capability to finish 3D printing projects in as fast as 1 day. Our commitment to efficiency ensures your designs come to life promptly.

The specifications of the 3D prints we produce are determined by the 3D printer you select. Our diverse range of 3D printing machines accommodates various sizes. For instance, our large format FDM 3D printers offer a substantial build area of up to 36 x 24 x 26 inches. Alternatively, larger SLA printers can handle prints of up to 29 x 25 x 21 inches. SLS unfilled reaches a maximum dimension of 13 inches, while the glass-filled SLS machine is capable of producing prints measuring 26 x 15 x 23 inches. The Industrial Polyjet printer provides a build area of up to 19 x 15 x 7 inches.

For optimal compatibility, we recommend submitting your files in STEP (.stp) or STL (.stl) formats. If your file is in another format, we advise converting it to either STEP or STL before submission to ensure a smooth and efficient 3D printing process.

When selecting the ideal 3D printing service, capital plays a crucial role in the decision-making process. Understanding various factors is key to determining the printing costs or the feasibility of outsourcing your project. These factors encompass your choice of 3D printer, the model’s size and design intricacy, the selected material, and the volume of parts in your project. Each of these elements contributes to the overall capital expenditure associated with your 3D printing endeavors.

Start a new project production today!

Explore 3D Prints Resrouces

At MY Prototyping, we design and create precise custom injection molds from high-quality materials. Our processes ensure unmatched consistency and repeatability at fast lead times and affordable pricing. Every plastic injection molding we fabricate meets international standards. From one-off projects to small batches and production tooling, we provide durable and reliable mold tools.