Rapid Prototyping and On-Demand Production for

Aerospace Industry

Get high-quality manufacturing services for your custom aerospace prototypes and production parts. Launch products faster, reduce risks, and streamline production processes with on-demand production at competitive prices.

Production-grade products

ISO 9001:2015 certiified

24/7 engineering support

- Home

- Industries

- Research

Why Choose RapidDirect

RapidDirect specializes in reliable aerospace part prototyping and production, ranging from simple to complex projects. We combine manufacturing expertise with advanced technologies and adherence to quality requirements to bring your ideas to life. Regardless of the end use of your aircraft parts, RapidDirect can help you reach your unique goals.

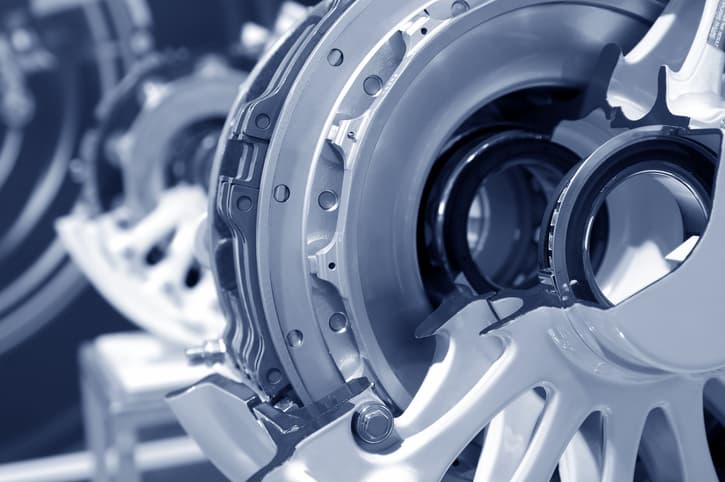

Strong Manufacturing Capabilities

As an ISO 9001 certified manufacturing company, RapidDirect’s production line features advanced technologies to ensure manufacturing accuracy and precision. Every aerospace part comes with the correct dimensional specifications, structural strength, and performance.

Strong Manufacturing Capabilities

As an ISO 9001 certified manufacturing company, RapidDirect’s production line features advanced technologies to ensure manufacturing accuracy and precision. Every aerospace part comes with the correct dimensional specifications, structural strength, and performance.

Strong Manufacturing Capabilities

As an ISO 9001 certified manufacturing company, RapidDirect’s production line features advanced technologies to ensure manufacturing accuracy and precision. Every aerospace part comes with the correct dimensional specifications, structural strength, and performance.

Strong Manufacturing Capabilities

As an ISO 9001 certified manufacturing company, RapidDirect’s production line features advanced technologies to ensure manufacturing accuracy and precision. Every aerospace part comes with the correct dimensional specifications, structural strength, and performance.

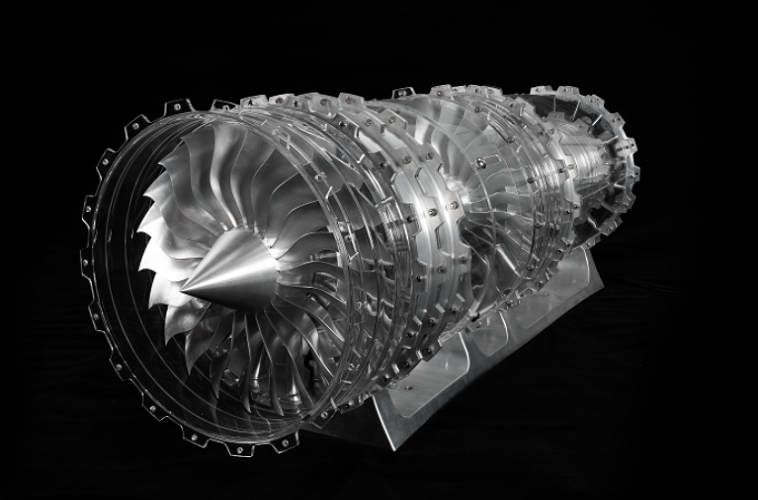

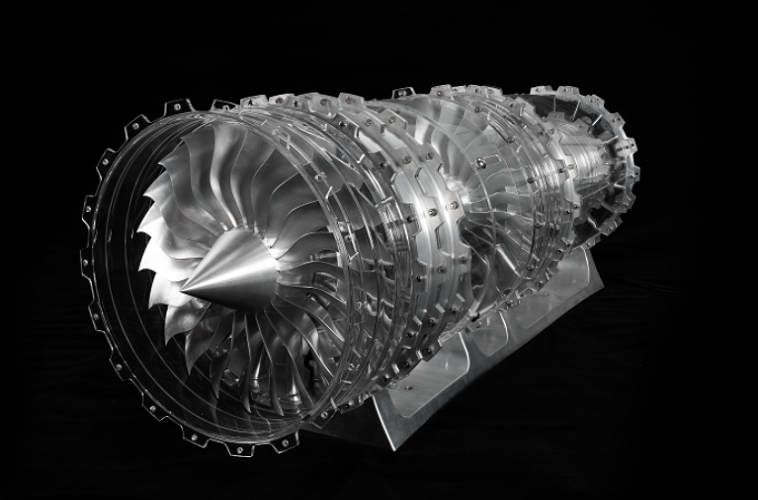

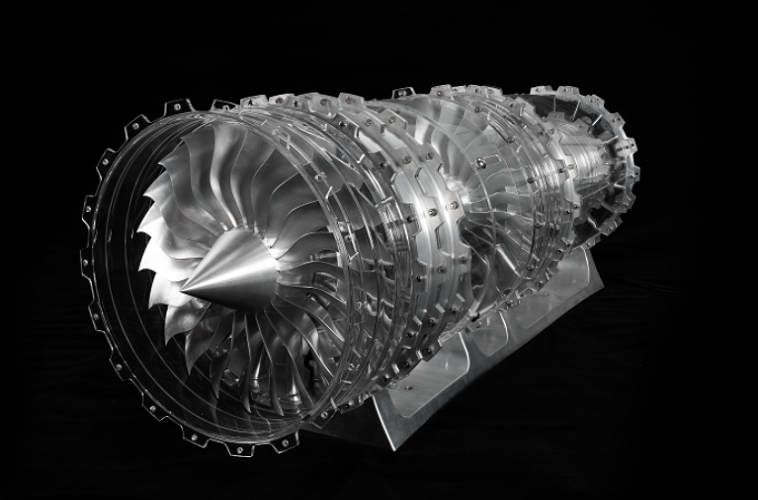

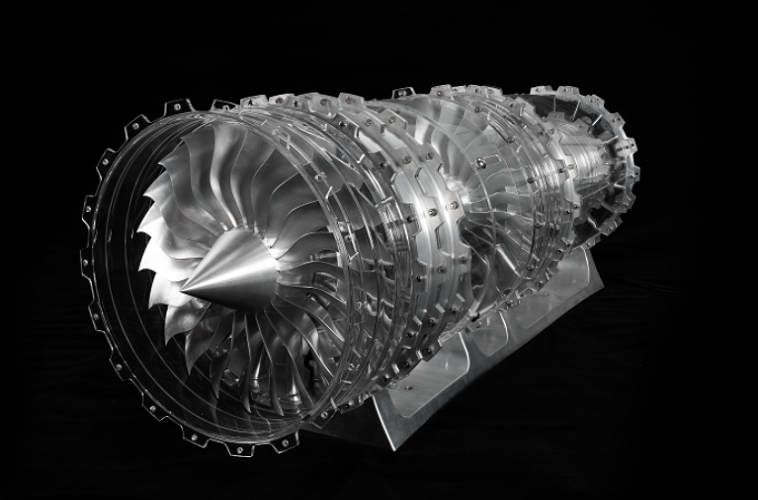

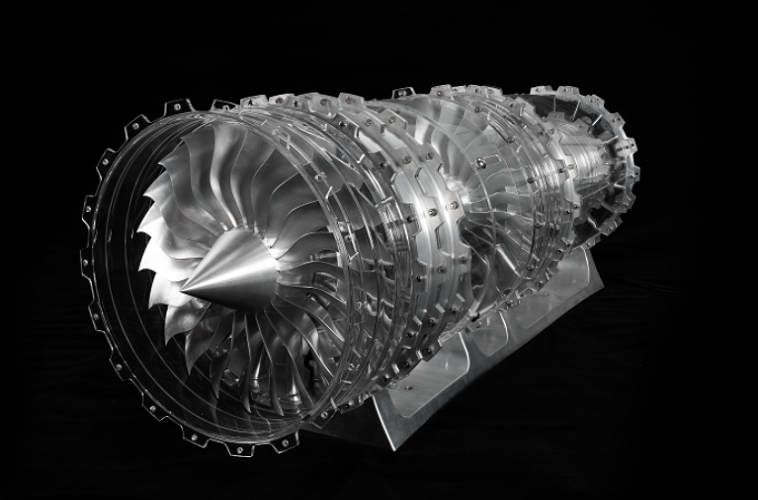

CNC Machined Aerospace Turbo Engine Prototype

RapidDirect championed the rapid prototyping of a high-end complex aerospace engine with high tolerance requirements. Despite the strict part assembly demands and complicated turbo blade programming, RapidDirect’s 5-axis CNC machining capabilities created a turbo engine that meets all industry demands.

Prototyping and Production Solutions for Aerospace Industry

Reliable solutions for new product development in the aerospace industry. Get expertly engineered custom prototypes and production parts with outstanding performance and durability. Our solutions span various production stages to meet your manufacturing goals.

Mass Production 1

Seamlessly move from product testing to mass production of end-use parts. Gain access to the adoption of precise quality requirements and rapid delivery of final products.

Mass Production

Seamlessly move from product testing to mass production of end-use parts. Gain access to the adoption of precise quality requirements and rapid delivery of final products.

High-Quality Custom End-use Parts

Tight Tolerances on Precision Machined Parts

Secondary Operations for Better Surface Requirements

Rigorous Inspection and Quality Control

Mass Production 2

Seamlessly move from product testing to mass production of end-use parts. Gain access to the adoption of precise quality requirements and rapid delivery of final products.

Mass Production

Seamlessly move from product testing to mass production of end-use parts. Gain access to the adoption of precise quality requirements and rapid delivery of final products.

High-Quality Custom End-use Parts

Tight Tolerances on Precision Machined Parts

Secondary Operations for Better Surface Requirements

Rigorous Inspection and Quality Control

Mass Production 3

Seamlessly move from product testing to mass production of end-use parts. Gain access to the adoption of precise quality requirements and rapid delivery of final products.

Mass Production

Seamlessly move from product testing to mass production of end-use parts. Gain access to the adoption of precise quality requirements and rapid delivery of final products.

High-Quality Custom End-use Parts

Tight Tolerances on Precision Machined Parts

Secondary Operations for Better Surface Requirements

Rigorous Inspection and Quality Control

Mass Production 4

Seamlessly move from product testing to mass production of end-use parts. Gain access to the adoption of precise quality requirements and rapid delivery of final products.

Mass Production

Seamlessly move from product testing to mass production of end-use parts. Gain access to the adoption of precise quality requirements and rapid delivery of final products.

High-Quality Custom End-use Parts

Tight Tolerances on Precision Machined Parts

Secondary Operations for Better Surface Requirements

Rigorous Inspection and Quality Control

Mass Production 5

Seamlessly move from product testing to mass production of end-use parts. Gain access to the adoption of precise quality requirements and rapid delivery of final products.

Mass Production

Seamlessly move from product testing to mass production of end-use parts. Gain access to the adoption of precise quality requirements and rapid delivery of final products.

High-Quality Custom End-use Parts

Tight Tolerances on Precision Machined Parts

Secondary Operations for Better Surface Requirements

Rigorous Inspection and Quality Control

Trusted by Fortune 500 Companies

Aircraft OEMs

Space technology companies

Satellite manufacturers and operators

Commercial aviation companies

Space launch operators

Unmanned aerial vehicle and drone delivery systems

Unmanned aerial vehicle and drone delivery systems

Aerospace Manufacturing Capabilities

Take advantage of our professional manufacturing services throughout the production cycle, from prototyping and design validation to functional testing and product launch. We deliver high-quality and precise flight-worthy components with fast turnaround and at low costs. With our quality control process, you can be sure of getting parts that meet your unique requirements.

CNC Machining

CNC Machining

CNC Machining

CNC Machining

CNC Machining

CNC Machining

CNC Machining

CNC Machining

Materials for Aerospace Components

These are commonly molded plastics that our injection molding service provides. After knowing the basics of materials, like common grades, brands, advantages, and disadvantages, choose the right injection molding material depending on your application requirements.

Tooling Materials

Before injection molding process starts low or high-volume production, a high tolerance CNC machined tooling is needed. Most commonly used materials include:

Tool Steel: P20, H13, S7, NAK80, S136, S136H, 718, 718H, 738 Stainless Steel: 420, NAK80, S136, 316L, 316, 301, 303, 304

Aluminum: 6061, 5052, 7075

Robotics 1

Our industrial-grade robotics prototyping and parts manufacturing services aid in the continuous evolution of the robotics market.

Robotics 2

Our industrial-grade robotics prototyping and parts manufacturing services aid in the continuous evolution of the robotics market.

Robotics 3

Our industrial-grade robotics prototyping and parts manufacturing services aid in the continuous evolution of the robotics market.

Robotics 4

Our industrial-grade robotics prototyping and parts manufacturing services aid in the continuous evolution of the robotics market.

Surface Finishing for Aerospace Parts

Get high-quality surface finishing for your aerospace components to improve the aesthetic qualities of your products. Our superior finishing services also improve the corrosion and wear resistance of these parts while improving their mechanical properties.

| Name | Description | Materials | Color | Texture | Link | |

|---|---|---|---|---|---|---|

| Anodizing | A grade finishes are made using a diamond buffing process and yield shiny and glossy surfaces on injection molded parts. | Aluminum | Clear, black, grey, red, blue, gold. | Smooth, matte finish. | Learn More>> |

| Powder Coating | B grade finishes use grit sandpaper to produce parts with a slightly rougher finish than grade A parts. Custom molded plastic parts that undergo B grade finishing have a matte surface texture. | Aluminum, Stainless Steel, Steel | Black, any RAL code or Pantone number | Gloss or semi-gloss | Learn More>> |

Aerospace Applications

Our manufacturing capabilities help accelerate the production of a wide range of aerospace components for unique applications. Here are some of the common aerospace applications:

Rapid tooling, brackets, chassis, and jigs

Heat exchangers

Heat exchangers

Conformal cooling channels

Turbo pumps and manifolds

Fit check gauges

Fuel nozzles

Gas and liquid flow components

See What Our Customers Say About Us

A customer’s words have a more substantial impact than a company’s claims – and see what our satisfied customers have said regarding how we fulfilled their requirements.

No MOQ

RapidDirect has been our molding partner for over 2 years. Since then, RapidDirect has regularly provided us with top-notch molded parts. In addition, RapidDirect has offered assembly services for various models of our multi-bit screwdrivers up until the final finished product. I am pleased to recommend RapidDirect to anyone looking for top-notch molded products.

Harri Rossi

– Engineer

No MOQ

RapidDirect has been our molding partner for over 2 years. Since then, RapidDirect has regularly provided us with top-notch molded parts. In addition, RapidDirect has offered assembly services for various models of our multi-bit screwdrivers up until the final finished product. I am pleased to recommend RapidDirect to anyone looking for top-notch molded products.

Harri Rossi

– Engineer

No MOQ

RapidDirect has been our molding partner for over 2 years. Since then, RapidDirect has regularly provided us with top-notch molded parts. In addition, RapidDirect has offered assembly services for various models of our multi-bit screwdrivers up until the final finished product. I am pleased to recommend RapidDirect to anyone looking for top-notch molded products.

Harri Rossi

– Engineer

No MOQ

RapidDirect has been our molding partner for over 2 years. Since then, RapidDirect has regularly provided us with top-notch molded parts. In addition, RapidDirect has offered assembly services for various models of our multi-bit screwdrivers up until the final finished product. I am pleased to recommend RapidDirect to anyone looking for top-notch molded products.

Harri Rossi

– Engineer

No MOQ

RapidDirect has been our molding partner for over 2 years. Since then, RapidDirect has regularly provided us with top-notch molded parts. In addition, RapidDirect has offered assembly services for various models of our multi-bit screwdrivers up until the final finished product. I am pleased to recommend RapidDirect to anyone looking for top-notch molded products.

Harri Rossi

– Engineer

No MOQ

RapidDirect has been our molding partner for over 2 years. Since then, RapidDirect has regularly provided us with top-notch molded parts. In addition, RapidDirect has offered assembly services for various models of our multi-bit screwdrivers up until the final finished product. I am pleased to recommend RapidDirect to anyone looking for top-notch molded products.

Harri Rossi

– Engineer

Custom Parts for Aerospace Industry

Brands and businesses in the aerospace industry rely on our manufacturing solutions for their unique requirements. From prototyping to mass production, we create parts that comply with industry performance and safety standards. Our extensive gallery shows precision-machined aerospace prototypes and production parts.

Let's Start A New Project Today

Explore More Industries We Support

Years of serving various clients gave us the experience and knowledge needed to support numerous industries. Click on the link below to know more.

Automotive

Consumer Goods

Medical Devices

Robotics

Explore Related Resources

How Precision Sheet Metal Fabrication Improves Modern Cars’ Performance

Precision sheet metal fabrication is one of the most important processes in automotive engineering, which makes it possible to fabricate …

How Rapid Injection Molding Lowers Production Costs in the Drone Industry?

Are high production costs and slow timelines keeping your drone business stuck on the ground? If so, Rapid Injection Molding …

ISO 2768-mk – The basics of the general tolerance standard

Every feature on a product or part has a size and a geometric shape. To ensure that the size and …